[Example] Resin parts

Introducing a case where we reduced costs and commercialized resin parts that were originally produced by another company!

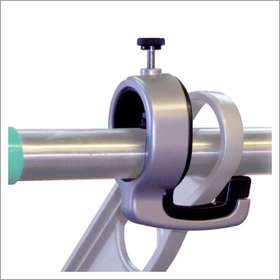

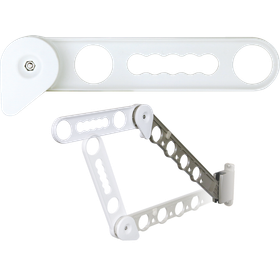

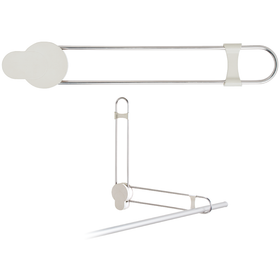

Originally, we received a request for a quote for "plastic parts" that were being produced by another company, in order to reduce costs. Our sales representative visited and provided a detailed explanation of how the proposal and drawings would change in 3D, and how it would impact the pricing. We proposed cost reduction by increasing work efficiency without lowering the product cost, and successfully produced the product. To date, we have produced over 10,000 products, creating 285 molds each year, which is almost one mold per day. We handle everything from product design to mold design. 【Case Study】 ■ Product: Plastic Parts ■ Request: Cost Reduction ■ Proposal: Presented with drawings and 3D models *For more details, please refer to the PDF document or feel free to contact us.

basic information

For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(2)

Download All CatalogsDistributors

Takara Sangyo Co., Ltd. engages in integrated production and sales from the manufacturing of plastic molded products and metal processed products to assembly. Takara Sangyo started with plastic molding. Leveraging our strengths in planning, development, production, and management, we have continued to challenge ourselves in "monozukuri" (the art of making things) for many years, taking on the planning and production of composite products that use metal. Established in 1994 as a wholly-owned subsidiary, Suzhou Takara leads a network of two factory locations. We have a strong reputation for domestic OEM achievements. With molding and mold technology and quality control comparable to domestic production, we meet the demands of OEM clients.