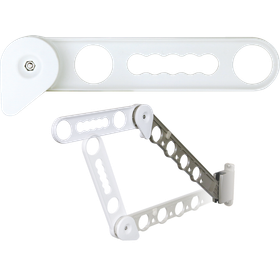

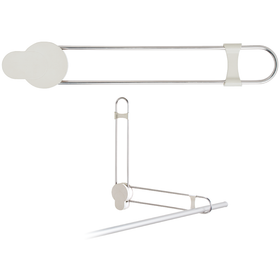

Four types of arm lengths, with two-stage movement possible! "Wall-mounted drying hardware for waist walls"

The arm length is designed to accommodate various balcony sizes, with a maximum extension from the wall of 250mm to 550mm! It can also be adjusted in two stages according to the intended use.

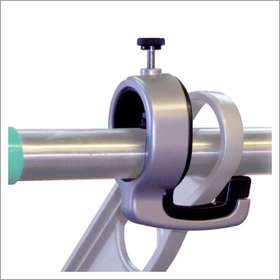

The "KBN Wall-Mounted Drying Hardware" from the "Selectable" drying hardware series offers four types to accommodate various balcony sizes. With five color variations, it suits any scene. The maximum extension from the wall of the arm is selectable in four types, ranging from 250mm to 550mm. The mounting brackets have been made narrower than conventional products to fit well with narrow railings. 【Colors】 ■ Black (K) ■ Dark Bronze (BKC) ■ Stainless Color (ST) ■ Silver (S) ■ White (W) 【Mounting Fasteners (Optional)】 ■ For Concrete ■ For Wood Substrates ■ For Posts: Through Bolt Set □50〈□70〉 ■ For Posts: Impulse Nut Set

basic information

【Basic Specifications】 ■KBN55 Dimensions: Maximum projection from the wall… 550mm Total weight: 1000g Material: Arm… Aluminum die-cast Caps… Polypropylene resin Laundry weight: 30kg ■KBN45 Dimensions: Maximum projection from the wall… 450mm Total weight: 900g Material: Arm… Aluminum die-cast Caps… Polypropylene resin Laundry weight: 30kg ■KBN35 Dimensions: Maximum projection from the wall… 350mm Total weight: 800g Material: Arm… Aluminum die-cast Caps… Polypropylene resin Laundry weight: 30kg ■KBN25 Dimensions: Maximum projection from the wall… 250mm Total weight: 700g Material: Arm… Aluminum die-cast Caps… Polypropylene resin Laundry weight: 30kg

Price range

Delivery Time

Applications/Examples of results

Wall-mounted clothes drying rack for waist installation.

Detailed information

catalog(2)

Download All CatalogsDistributors

Takara Sangyo Co., Ltd. engages in integrated production and sales from the manufacturing of plastic molded products and metal processed products to assembly. Takara Sangyo started with plastic molding. Leveraging our strengths in planning, development, production, and management, we have continued to challenge ourselves in "monozukuri" (the art of making things) for many years, taking on the planning and production of composite products that use metal. Established in 1994 as a wholly-owned subsidiary, Suzhou Takara leads a network of two factory locations. We have a strong reputation for domestic OEM achievements. With molding and mold technology and quality control comparable to domestic production, we meet the demands of OEM clients.