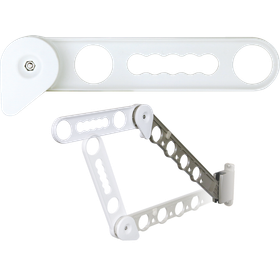

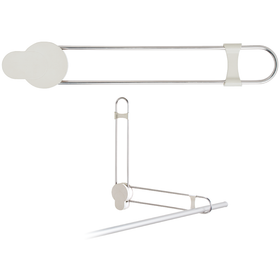

Indoor clothes drying rack with a rod. Easy to install, so it can be set up by one person! The rod is collapsible.

Expand the ceiling hanging space. The "indoor clothes drying rack with rod" comes in two widths: 'TFG1209' with a rod width of 120cm and 'TFG0609' with a rod width of 60cm.

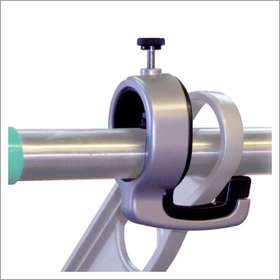

A new product has arrived from the Choi Boshi HOSETA "Rod-Equipped Indoor Drying Rack TF0090"! The "Rod-Equipped Indoor Drying Rack TFG1209/TFG0609" is lightweight despite having a rod, and can be easily installed with simple DIY. Previously, we only offered small sizes specialized for quick drying, but in response to requests for more drying space, we present a new version with a larger and more refined design. 【Features】 ■ Available in 2 sizes ■ Easy to install by one person ■ Comes with hooks for storing operation cords *Note: You cannot raise or lower it while clothes are hanging.

basic information

【Clothes Drying Hardware Lineup】 ■ Indoor Drying TJ: Hanging Type Indoor Drying Hardware LP: Indoor Expandable Rod TG: Adjustable Indoor Drying TM: Adjustable Drying Hardware ■ Outdoor Drying KAN: Window Wall Drying Hardware KBN: Waist Wall Drying Hardware SF: Movable Waist Wall Drying Hardware SFK-P: Movable Pole for Waist Wall TJEX: Hanging Type Outdoor Drying *For more details, please refer to the materials. Feel free to contact us with any inquiries.

Price range

Delivery Time

Applications/Examples of results

*For more details, please refer to the materials. Feel free to contact us as well.*

Related Videos

catalog(1)

Download All CatalogsDistributors

Takara Sangyo Co., Ltd. engages in integrated production and sales from the manufacturing of plastic molded products and metal processed products to assembly. Takara Sangyo started with plastic molding. Leveraging our strengths in planning, development, production, and management, we have continued to challenge ourselves in "monozukuri" (the art of making things) for many years, taking on the planning and production of composite products that use metal. Established in 1994 as a wholly-owned subsidiary, Suzhou Takara leads a network of two factory locations. We have a strong reputation for domestic OEM achievements. With molding and mold technology and quality control comparable to domestic production, we meet the demands of OEM clients.