news list

1~17 item / All 17 items

-

Lightweight and durable solutions for the harsh environment of Kochi Prefecture.

Grace Solar has applied its years of technical expertise in aluminum alloy mounting systems to the aluminum alloy single-leg driven pile mounting system for a mountainous solar power generation project in Kochi Prefecture. This solution significantly reduces the difficulty of construction in complex terrains and realizes mountain installations based on the philosophy of "precise adaptation and environmental consideration." Adaptation to Mountainous Terrain In the diverse and undulating ground conditions of Kochi Prefecture, the Grace Solar team conducted precise geological surveys in advance and implemented optimal driven pile designs tailored to the project. The depth and angle of each pillar were meticulously calculated to ensure solid support on slopes while minimizing soil disturbance and protecting the fragile mountain ecosystem. Enhanced Wind and Seismic Resistance The design fully complies with Japan's strict solar mounting standards (JIS) and has undergone dynamic wind tunnel simulations and seismic response analyses. During the execution of the project, Grace Solar closely collaborated with local partners to overcome numerous challenges, including narrow construction environments and work during the rainy season. Modular pre-assembly and standardized installation processes significantly improved work efficiency in complex terrains, achieving grid connection as planned.

-

Grace Solar Racks Take Root in Chiba

In Chiba Prefecture, located in the Kanto region of Japan, multiple ground-mounted power plants using Grace Solar's aluminum alloy solar mounting systems have been successfully completed and have begun transmitting power. To address the high salinity and humidity of the marine climate, Grace Solar has specially improved the surface treatment and structural sealing of the mounting systems. The aluminum alloy body is coated with a multi-layer anti-corrosion coating, and salt damage prevention designs are employed at critical joint areas. This effectively prevents the intrusion of corrosive media, maintaining long-term structural stability and performance even in harsh corrosive environments. Grace Solar optimizes the wind resistance performance of the mounting system through wind tunnel simulations and structural calculations. By reinforcing joints and improving force distribution, the system can reliably withstand strong wind loads, ensuring the safe operation of power plants even in adverse weather conditions. Considering the soft ground and high groundwater levels in coastal areas, Grace Solar provides foundation solutions and construction methods tailored to the site, ensuring the stability of the mounting system even under complex geological conditions. Additionally, the use of lightweight aluminum materials and modular design significantly enhances construction efficiency and adaptability in coastal environments.

-

How do you determine the arrangement of solar panels?

Horizontal and Vertical Placement The arrangement direction of the modules is fundamental to solar power system design and is mainly divided into two formats: horizontal and vertical. Rows and Columns Planning the array scale is a balance of light, shadow, and space. The number of tiers (in the north-south direction) must be comprehensively considered based on geographical location, solar altitude angle, and the influence of shadows in front and behind. For example, in most regions of China, a configuration of four tiers as one unit for horizontal arrays is common. Angle and Height The installation angle of the modules and the height above the ground are important parameters that affect the system's power generation performance and operational stability. The tilt angle of the modules is set not for aesthetic reasons, but to maximize solar radiation capture. Beyond standard designs, there are also flexible responses based on specific needs. In special situations where land is limited, appropriately reducing the tilt angle can improve land utilization. The arrangement of solar mounting structures impacts the "lifeline of power generation" for the power plant, forming the foundation for each unit of electricity generated by its structure. It is not merely a regular arrangement of modules, but an engineering poem crafted by Grace Solar under the sunlight, with each piece telling its own story.

-

Italy Ravenna Project Case: Successful Implementation of Grace Solar's Elevated Tracker

In Ravenna, northern Italy, Grace Solar successfully implemented a solar power plant project equipped with a tracking system using its elevated installation tracker. The project site in Ravenna is at a low elevation and is prone to localized flooding during the rainy season, which posed a risk of submersion for conventional low mounting systems. Grace Solar's elevated tracker effectively prevents erosion of the electrical systems, solar modules, and drive components from surface water by raising the ground clearance, while also ensuring room for local vegetation growth and ecological compatibility. The system adopted for this project features an intelligent tracking algorithm that adjusts the panel angles in real-time based on the sun's position and weather conditions, achieving an approximately 15% to 20% increase in energy generation compared to conventional fixed mounting systems. Moving forward, Grace Solar will focus on the climatic characteristics and topographical conditions of Southern Europe and the Mediterranean region, aiming to provide more customized, high-efficiency mounting solutions, and will strive to help solar power plants worldwide achieve higher energy yields and ensure long-term operational reliability.

-

Response to mountain challenges: Grace Solar mounting system debuts in Tochigi Prefecture.

In Tochigi Prefecture, located in the northern part of the Kanto region, several ground-mounted power plants utilizing Grace Solar's aluminum alloy solar mounting systems are being constructed smoothly and have begun operations. Grace Solar planned the tilt angles and foundation types of the mounting systems based on precise topographical and meteorological data from the design stage. The high-strength aluminum alloy mounting systems are lightweight yet effectively suppress snow accumulation, ensuring stable operation of the system even during harsh winter conditions. The aluminum alloy mounting systems adopted in this project are treated with a special anti-corrosion coating on the surface, allowing them to adapt to the environment of Tochigi Prefecture, which experiences significant temperature differences and seasonal humidity changes. This effectively delays material degradation and extends the overall lifespan of the system. Going forward, Grace Solar will continue to focus on the characteristics and environmental requirements of each region, supporting more solar power generation projects in Japan and around the world through customized mounting solutions, and providing sustainable and reliable support for renewable energy infrastructure.

-

The tracking system of Grace Solar maximizes power generation efficiency.

In terms of the number and arrangement of drive sources in the drive system, tracking systems are mainly classified into single-point drive and multi-point drive. These two methods are the mainstream choices in large-scale ground-mounted power plants worldwide due to their superior balance of power generation improvement, initial investment, and reliability, making them the solutions strongly recommended by Grace Solar—solar tracking systems. As the names suggest, single-point drive and multi-point drive use rotating drive devices to synchronously rotate the mounting structure. An optimized power transmission design effectively ensures the accuracy of the synchronous movement of the mounting structure. By continuously reducing the angle of incidence of sunlight, they effectively enhance solar yield. Grace Solar's independently developed independent single-row tracking mounting system and multi-point drive tracking mounting system can accommodate slopes of up to 20% in the north-south direction while maintaining a low posture close to the ground, demonstrating excellent wind resistance. The number of modules installed can be adjusted according to the string configuration and the size of the terrain, making it an optimal choice for power plants on irregularly shaped land.

-

Chiba Prefecture Ground Power Station: Grace Solar, responding with quality.

In Chiba Prefecture, the core economic area of Japan, multiple ground-mounted solar power plants utilizing Grace Solar's aluminum alloy solar mounting systems have been completed one after another and are continuing stable operations. Grace Solar's project team conducted detailed geological surveys and systematic structural calculations during the initial planning phase. Their aluminum alloy solar mounting system effectively responds to the soil characteristics of various regions due to its excellent corrosion resistance and structural adaptability. During the construction process, the team strictly adhered to Japan's solar installation standards, strongly supporting the smooth advancement of the project and receiving high praise from partners. This mounting system employs high-quality aluminum alloy materials, ensuring excellent structural strength and outstanding corrosion performance, making it particularly suitable for coastal environmental conditions. Additionally, it achieves a perfect balance between lightweight design and high strength. This not only reduces the foundation load but also significantly improves on-site installation efficiency through modular design, shortening the construction period. Its exceptional long-term durability fundamentally guarantees the power generation revenue throughout the entire lifecycle of the solar power plants, providing customers with long-term and stable investment value.

-

Industry Commentary | How to Choose the Best Solar Mounting System for Diverse Roofs

With the spread of decentralized power generation, rooftop solar systems have become a popular clean energy solution for households and businesses. An excellent mounting system must meet three core requirements: structural strength, environmental adaptability, and ease of installation. Grace Solar leverages years of technological accumulation to provide comprehensive mounting solutions tailored to various roof characteristics, supporting the safe and stable operation of solar systems. We offer a mature product lineup that caters to a wide range of scenarios, from residential roofs to industrial roofs. For tile roofs, we employ a non-destructive installation design and a patented hook system that perfectly fits the structure of the tiles. Our lightweight aluminum alloy mounting systems reduce weight by 45% compared to traditional steel structures while maintaining strength and ensuring safety with a design that evenly distributes loads. For metal roofs, we have developed an adaptive clamp system that accommodates various shapes. With the diversification of solar applications, Grace Solar continues to innovate, providing safer, more efficient, and cost-effective all-scenario solutions, contributing to the promotion of green energy.

-

Industry Commentary | Durability Issues of Solar Mounting Structures and Grace Solar's Technical Solutions

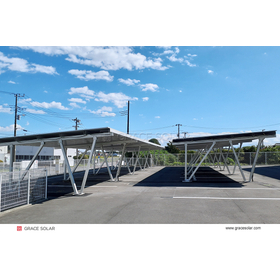

From strong wind vibrations and roof loads to extreme climates in complex terrains, Grace Solar is always pursuing smarter, more efficient, and durable mounting systems. Challenge 1: Deformation of mounting systems in strong wind environments Grace Solar's solution: ▸ Smart wind load analysis ▸ Wind-resistant structural design (RWDI certified) Case study: 4.5MW rooftop distributed solar power plant in the Philippines Challenge 2: Decreased installation efficiency in complex terrains Grace Solar's solution: ▸ Design that eliminates the need for slope adjustment ▸ Over 20 terrain-adaptive solutions Case study: 55MW large-scale mountainous solar power project in Japan Challenge 3: High maintenance costs for tracking systems Grace Solar's solution: ▸ Real-time monitoring ▸ Modular design Case study: Solar power plant project in Italy Challenge 4: Snow accumulation affecting system safety and power generation efficiency Grace Solar's solution: ▸ Snow-resistant structure ▸ Snow melting solutions Case study: Solar parking lot project in Fukushima, Japan

-

Framework Encyclopedia | When Solar Mounts Changed to "Lightweight"

The reason aluminum alloys are widely used in solar power generation projects is that they are lightweight yet strong, have excellent robustness, corrosion resistance, and oxidation resistance, and are easy to install. 1. Impact from heavy snow and strong winds? Based on conditions such as wind speed, snowfall, and installation angle in the installation area, structural calculations for the framework are performed in accordance with building load standards to meet design requirements. 2. Corrosion in humid areas? The corrosion resistance of aluminum frames can be improved by enhancing the plating process or increasing the plating thickness. For example, by applying processes such as anodizing, electrophoretic painting, and composite films, a protective layer is formed on the surface of the components. 3. Deformation due to extreme high temperatures? Thermal expansion is primarily affected by factors such as length and temperature. The longest members in the structure are the purlins, and by leaving gaps between the purlins during installation, structural failure due to thermal expansion can be prevented. 4. Uneven and unstable ground? The more accurate the environmental parameters provided during the design phase, the more stable the aluminum alloy frame will be after installation. For example, on uneven ground, the increase in wind load on slopes is calculated to ensure strength.

-

Project Achievements | Grace Solar's Ibaraki "Aluminum" Journey

Under the sunlight of Ibaraki Prefecture, Japan, a group of "Metal Heroes" is rewriting the scenario of the new energy industry. As a key player in the region's solar power construction, Grace Solar supports the stable operation of multiple ground-mounted solar power plants in the prefecture with its uniquely developed aluminum ground mounting system. Our solutions are currently driving the "story of transformation" in the energy industry. The 6005-T5 aluminum mounting system specially developed by Grace Solar employs a dual protective coating of anodizing and powder coating, forming a dense protective layer on the surface. It maintains durability for over 25 years even in high salinity coastal environments. The patented ground screw, with its unique screw structure and surface treatment technology, ensures a strong bond with the soil while exhibiting excellent corrosion resistance against underground moist environments. In this new stage of development, Grace Solar is exploring further possibilities in Ibaraki Prefecture. The core philosophy is to "create maximum energy value with the smallest ecological footprint." From the initial pilot project to the current scale expansion, we are responding to the development of Ibaraki Prefecture through technological innovation.

-

How to choose equipment racks? The answer is in Utsunomiya.

In the northern part of the Kanto Plain, in Utsunomiya City, Tochigi Prefecture, a solar power plant utilizing Grace Solar's CT foundation single-pole ground installation system is operating steadily. Utsunomiya City, one of Japan's important industrial hubs, has extremely high demands for quality and reliability in infrastructure, and this project fully demonstrates the exceptional capabilities of Grace Solar products in addressing complex geological conditions and high standards. The innovative design of the CT single-pole system effectively adapts to the local soil characteristics, ensuring the robustness of the foundation. During construction, the team strictly adhered to Japan's solar installation standards, establishing a solid foundation for the smooth delivery of the project by ensuring the precision of each construction task. This mounting system optimizes structural mechanical design, guaranteeing support strength while significantly reducing the amount of materials used and on-site work, thereby improving construction efficiency. It ensures particularly excellent pressure resistance against common environmental factors in Japan, such as seasonal rainfall, guaranteeing the long-term stability of the solar power plant under various conditions.

-

Project Achievements | Shizuoka Prefecture: When Photosynthesis Takes Root in an Industrial City

In the factory cluster of Hamamatsu City, Shizuoka Prefecture, a solar power generation system supported by Grace Solar's mounting structures is transforming the energy landscape of this industrial city. Technological Innovation Supporting the Transformation of an Industrial City Grace Solar's ground-mounted structures maximize power generation efficiency in limited spaces through precise design and smart manufacturing. With special alloys and anti-corrosion treatment, they can withstand salt damage and typhoons in Shizuoka's coastal areas. The installation accuracy and speed have exceeded the expectations of local partners, establishing a new standard for solar power generation in industrial zones. Industrial Aesthetics of the Installation Site Engineers pre-assemble units on the ground. The unflipped matte silver aluminum frames showcase the essential geometric beauty of industrial design. Co-creation for a Sustainable Future This project not only provides clean energy but also demonstrates new possibilities for the industrial city. Grace Solar will continue to promote global decarbonization with excellent products and services.

-

Industry Commentary | Advantages of Carbon Steel Solar Mounting Structures

High Strength, Low Cost: The Economic Advantages of Carbon Steel Frames Carbon steel is inherently strong, and this high structural strength ensures stable wind resistance while allowing for a simple support structure, reducing the need for extra components. This also lowers the wear rate during transportation, enabling further savings in material costs and installation expenses. Transportation and Construction: Streamlining the Entire Project The advantages of carbon steel frames are also evident in the transportation and construction phases. Standardized designs simplify on-site installation and shorten construction periods. For example, carbon steel frames can be packaged using a combination of wooden sticks and iron ties, improving unloading efficiency and increasing transport volume. This reduces construction time and labor costs, distributing the overall burden of the project across all stages. Technological Innovation: Breakthroughs in Corrosion Resistance With the evolution of material technology, the corrosion treatment of carbon steel frames has also significantly advanced. Grace Solar has adapted to the technological trends in process development, and all current carbon steel frames utilize AlMgZn coating. At the same time, to meet the special requirements of each project, our company offers custom options for hot-dip galvanizing.

-

Suwano City 1MW Mega Solar: How to respond to typhoon weather?

Maximizing Space Utilization with Energy Density Despite being a 1MW project scale, Grace Solar has packed optimal solutions for space utilization. The high-density arrangement minimizes the impact on the ground while maximizing power generation efficiency. Each piling position is precisely calculated to achieve the highest energy output on limited land. Wisdom of a Lightweight Yet Robust Structure Facing frequent typhoons and winter snowfall in Shizuoka, the standalone column piling system demonstrates structural resilience beyond its scale. With special aluminum alloy materials and patented surface treatment technology, it offers excellent weather resistance and corrosion resistance, addressing harsh environmental challenges. Globally Experienced, Locally Adapted Grace Solar leverages project experience from around the world to seamlessly integrate local needs with international standards. The system strictly adheres to Japanese building codes and seismic standards, obtaining certifications such as JIS and TÜV. This demonstrates the deep fusion of Chinese manufacturing technology and Japanese quality.

-

Industry Commentary | Misunderstandings Surrounding "Frames"

Misunderstanding 1: The mounting structure is merely a "support structure" with low technical requirements. High-quality solar mounting systems require multidisciplinary knowledge, including structural mechanics, materials science, and environmental engineering. Additionally, attention must be paid to component compatibility issues, and the mounting system must ensure sufficient adjustment tolerance and structural redundancy. Misunderstanding 2: The thicker the steel used in the mounting structure, the better the wind resistance. This indicates that the core of wind resistance lies in the scientific nature of structural design, rather than simply relying on the accumulation of materials. Misunderstanding 3: The lower the cost of the mounting structure, the better the overall economics of the project. In a certain ground-mounted power generation project, the use of a low-cost mounting structure resulted in excessive tolerance in hole positioning during installation, significantly reducing panel installation efficiency and increasing labor hours by 15%. As a result, the overall cost exceeded that of higher-quality competing products. Misunderstanding 4: The thicker the anti-corrosion coating, the better. In reality, different environments, such as industrial areas, coastal regions, and deserts, require anti-corrosion measures that are "tailored to fit." A good anti-corrosion design should be a precise matching of material properties and environmental requirements.

-

Exhibition Report | Grace Solar Showcases Innovative Solutions at ASEW Bangkok

From July 2 to 4, the large-scale event "ASIA Sustainable Energy Week (ASEW) 2025" in the field of sustainable energy in Asia was held at the QSNCC exhibition center in Bangkok, Thailand. Grace Solar, the global leader in solar mounting systems (booth number: W7), showcased innovative rooftop and ground-mounted solutions, attracting the attention of many industry stakeholders. To cater to the Southeast Asian market, they have established a local service team to support the entire process from design to construction. During the exhibition, Grace Solar formed collaborations with numerous energy companies to jointly develop solar power generation solutions better suited to local demand. As one of the top five companies in the global solar mounting sector, Grace Solar has a cumulative installation record of over 48 GW and has achieved a growth rate of 45% annually in the Southeast Asian market. This exhibition aimed to provide more tailored solutions for the Southeast Asian market, assisting in the spread and development of solar power applications in the region and injecting new energy into the local energy transition.