- PRODUCT

Framework Encyclopedia | When Solar Mounts Changed to "Lightweight"

厦門グレースソーラーテクノロジー有限会社

The reason aluminum alloys are widely used in solar power generation projects is that they are lightweight yet strong, have excellent robustness, corrosion resistance, and oxidation resistance, and are easy to install. 1. Impact from heavy snow and strong winds? Based on conditions such as wind speed, snowfall, and installation angle in the installation area, structural calculations for the framework are performed in accordance with building load standards to meet design requirements. 2. Corrosion in humid areas? The corrosion resistance of aluminum frames can be improved by enhancing the plating process or increasing the plating thickness. For example, by applying processes such as anodizing, electrophoretic painting, and composite films, a protective layer is formed on the surface of the components. 3. Deformation due to extreme high temperatures? Thermal expansion is primarily affected by factors such as length and temperature. The longest members in the structure are the purlins, and by leaving gaps between the purlins during installation, structural failure due to thermal expansion can be prevented. 4. Uneven and unstable ground? The more accurate the environmental parameters provided during the design phase, the more stable the aluminum alloy frame will be after installation. For example, on uneven ground, the increase in wind load on slopes is calculated to ensure strength.

- Date and time

- Capital

- Entry fee

Related product information

-

Roof-mounted solar panel system <Ballasted mounting system>

Roof-mounted solar panel system <Ballasted mounting system>Lightweight, flexible, and also strong and durable!

【Other Specifications】 ■Corrosion-resistant treatment: Anodizing & Stainless Steel ■Color tone: Natural color or custom ■Reference standard: JIS C 8955: 2017 ■Quality assurance: 10-year quality guarantee ■Usage time: Over 20 years *For more details, please download the PDF or feel free to contact us.

-

Roof-mounted solar panel system <triangular frame>

Roof-mounted solar panel system <triangular frame>Lightweight, flexible, and also strong and durable!

【Other Specifications】 ■Corrosion-resistant treatment: Anodizing & Stainless Steel ■Color tone: Natural color or custom ■Reference standard: JIS C 8955: 2017 ■Quality assurance: 10-year quality guarantee ■Usage time: Over 20 years *For more details, please download the PDF or feel free to contact us.

-

Inclined roof support system <angle adjustable>

Inclined roof support system <angle adjustable>Since it is a high-level pre-assembly, installation is convenient, saving labor costs and installation time!

【Other Specifications】 ■Corrosion-resistant treatment: Anodizing & Stainless Steel ■Color tone: Natural color or custom ■Reference standard: JIS C 8955:2017 ■Quality assurance: 10-year quality guarantee ■Service life: Over 20 years *For more details, please download the PDF or feel free to contact us.

-

Inclined Roof Support System <Commercial Use / Industrial Use>

Inclined Roof Support System <Commercial Use / Industrial Use>It is suitable for folded plate roofs such as gable roofs, sewn seam roofs, and standing seam roofs.

【Other Specifications】 ■Corrosion-resistant treatment: Anodizing & Stainless Steel ■Color tone: Natural color or custom ■Reference standard: JIS C 8955: 2017 ■Quality assurance: 10-year quality guarantee ■Usage time: Over 20 years *For more details, please download the PDF or feel free to contact us.

-

Inclined Roof Support System <Commercial Use・Industrial Use>

Inclined Roof Support System <Commercial Use・Industrial Use>Suitable for trapezoidal, wavy, and other shaped corrugated sheets.

【Other Specifications】 ■Corrosion-resistant treatment: Anodizing & Stainless Steel ■Color tone: Natural color or custom ■Reference standard: JIS C 8955: 2017 ■Quality assurance: 10-year quality guarantee ■Usage time: Over 20 years *For more details, please download the PDF or feel free to contact us.

-

Inclined Roof Support System <For Residential Use>

Inclined Roof Support System <For Residential Use>High safety, pre-assembled for easy installation!

【Other Specifications】 ■Corrosion Resistance Treatment: Anodizing & Stainless Steel ■Color Tone: Natural Color or Custom ■Reference Standard: JIS C 8955: 2017 ■Quality Assurance: 10-Year Quality Guarantee ■Service Life: Over 20 Years *For more details, please download the PDF or feel free to contact us.

-

Inclined solar sharing frame <aluminum alloy>

Inclined solar sharing frame <aluminum alloy>The structure is sturdy and durable, and with few installation steps, it can be completed in a short time!

【Other Specifications】 ■Corrosion Resistance Treatment: Anodizing or Electrophoretic Coating ■Color Tone: Natural Color or Customized ■Base: Concrete Ground Screw ■Reference Standard: JIS C 8955:2017 ■Quality Assurance: 10-Year Quality Guarantee *For more details, please download the PDF or feel free to contact us.

-

Achieving excellent strength and corrosion resistance! Ground-mounted rack system (universal type)

Achieving excellent strength and corrosion resistance! Ground-mounted rack system (universal type)Pre-assembled system that eliminates the need for on-site cutting, reducing labor by 50%, with a 10-year warranty for a general-purpose ground mounting system.

For more details, please contact us or download the catalog.

-

Segmented solar sharing frame <aluminum alloy>

Segmented solar sharing frame <aluminum alloy>The structure is sturdy and durable, and with few installation steps, it can be completed in a short time!

【Other Specifications】 ■Corrosion Resistance Treatment: Anodizing or Electrophoretic Coating ■Color Tone: Natural Color or Customized ■Base: Concrete Ground Screw ■Reference Standard: JIS C 8955:2017 ■Quality Assurance: 10-Year Quality Guarantee *For more details, please download the PDF or feel free to contact us.

-

CAR Waterproof Carport <Aluminum Alloy>

CAR Waterproof Carport <Aluminum Alloy>Lightweight, easy to install, and completed quickly!

【Other Specifications】 ■Corrosion Resistance Treatment: Anodizing or Electrophoretic Coating ■Color Tone: Natural Color or Customized ■Base: Concrete Ground Screw ■Reference Standard: JIS C 8955: 2017 ■Quality Assurance: 10-Year Quality Guarantee *For more details, please download the PDF or feel free to contact us.

-

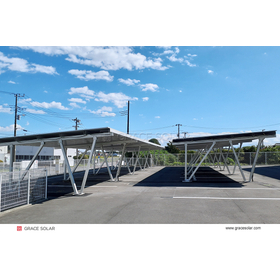

Two-Book Waterproof Carport <Aluminum Alloy>

Two-Book Waterproof Carport <Aluminum Alloy>Lightweight, easy to install, and completed quickly!

【Other Specifications】 ■Corrosion Resistance Treatment: Anodizing or Electrophoretic Coating ■Color Tone: Natural Color or Customized ■Base: Concrete Ground Screw ■Reference Standard: JIS C 8955: 2017 ■Quality Assurance: 10-Year Quality Guarantee *For more details, please download the PDF or feel free to contact us.

-

Type II Carport <Aluminum Alloy>

Type II Carport <Aluminum Alloy>Lightweight, easy to install, and completed quickly!

【Other Specifications】 ■Corrosion Resistance Treatment: Anodizing or Electrophoretic Coating ■Color Tone: Natural Color or Customized ■Base: Concrete Ground Screw ■Reference Standard: JIS C 8955: 2017 ■Quality Assurance: 10-Year Quality Guarantee *For more details, please download the PDF or feel free to contact us.

-

Type A Land Use Stand - Horizontal Placement <Aluminum Alloy>

Type A Land Use Stand - Horizontal Placement <Aluminum Alloy>Lightweight, structurally stable, and low transportation and installation costs!

【Other Specifications】 ■Corrosion Resistance Treatment: Anodic oxidation treatment or electrophoretic treatment ■Color Tone: Natural color or customized ■Base: Concrete Ground screw ■Reference Standard: JIS C 8955: 2017 ■Quality Assurance: 10-year quality guarantee *For more details, please download the PDF or feel free to contact us.

-

Type A Land Use Stand - Vertical Placement <Aluminum Alloy>

Type A Land Use Stand - Vertical Placement <Aluminum Alloy>Lightweight, structurally stable, and low transportation and installation costs!

【Other Specifications】 ■Corrosion Resistance Treatment: Anodizing or Electrophoretic Coating ■Color Tone: Natural Color or Customized ■Base: Concrete Ground Screw ■Reference Standard: JIS C 8955:2017 ■Quality Assurance: 10-Year Quality Guarantee *For more details, please download the PDF or feel free to contact us.

-

Type VV Land Use Frame - Horizontal Placement <Aluminum Alloy>

Type VV Land Use Frame - Horizontal Placement <Aluminum Alloy>Lightweight, with low transportation and installation costs!

【Other Specifications】 ■Corrosion Resistance Treatment: Anodizing or Electrophoretic Coating ■Color Tone: Natural Color or Customized ■Base: Concrete Ground Screw ■Reference Standard: JIS C 8955: 2017 ■Quality Assurance: 10-Year Quality Guarantee *For more details, please download the PDF or feel free to contact us.

-

Type N Land Use Stand - Vertical Placement <Aluminum Alloy>

Type N Land Use Stand - Vertical Placement <Aluminum Alloy>Simple structure, lightweight, easy to install, and completed quickly!

【Other Specifications】 ■Corrosion Resistance Treatment: Anodizing or Electrophoretic Coating ■Color Tone: Natural Color or Customized ■Base: Concrete Ground Screw ■Reference Standard: JIS C 8955:2017 ■Quality Assurance: 10-Year Quality Guarantee *For more details, please download the PDF or feel free to contact us.

-

Type VV Land Use Frame - Vertical Placement <Aluminum Alloy>

Type VV Land Use Frame - Vertical Placement <Aluminum Alloy>Lightweight, with low transportation and installation costs!

【Other Specifications】 ■Corrosion Resistance Treatment: Anodizing or Electrophoretic Coating ■Color Tone: Natural Color or Customized ■Base: Concrete Ground Screw ■Reference Standard: JIS C 8955: 2017 ■Quality Assurance: 10-Year Quality Guarantee *For more details, please download the PDF or feel free to contact us.

-

Type N Land Use Stand - Horizontal <Aluminum Alloy>

Type N Land Use Stand - Horizontal <Aluminum Alloy>Simple structure, lightweight, easy to install, and completed quickly!

【Other Specifications】 ■Corrosion Resistance Treatment: Anodizing or Electrophoretic Treatment ■Color Tone: Natural Color or Customized ■Base: Concrete Ground Screw ■Reference Standard: JIS C 8955:2017 ■Quality Assurance: 10-Year Quality Guarantee *For more details, please download the PDF or feel free to contact us.

-

Type W Land Use Stand - Horizontal Placement <Aluminum Alloy>

Type W Land Use Stand - Horizontal Placement <Aluminum Alloy>Flexible layout style, fewer installation steps, and quick completion!

【Other Specifications】 ■Corrosion Resistance Treatment: Anodizing or Electrophoretic Treatment ■Color Tone: Natural Color or Customized ■Base: Concrete Ground Screw ■Reference Standard: JIS C 8955:2017 ■Quality Guarantee: 10-Year Quality Guarantee *For more details, please download the PDF or feel free to contact us.

-

Type W Land Use Stand - Vertical Placement <Aluminum Alloy>

Type W Land Use Stand - Vertical Placement <Aluminum Alloy>Flexible layout style, fewer installation steps, and quick completion!

【Other Specifications】 ■Corrosion Resistance Treatment: Anodizing or Electrophoretic Coating ■Color Tone: Natural Color or Customized ■Base: Concrete Ground Screw ■Reference Standard: JIS C 8955: 2017 ■Quality Assurance: 10-Year Quality Guarantee *For more details, please download the PDF or feel free to contact us.

-

Footless land platform - horizontal placement <aluminum alloy>

Footless land platform - horizontal placement <aluminum alloy>Lightweight and easy to install!

【Other Specifications】 ■Corrosion-resistant treatment: Anodizing or electrophoretic treatment ■Color tone: Natural color or customized ■Base: Concrete Ground screw ■Reference standard: JIS C 8955: 2017 ■Quality assurance: 10-year quality guarantee *For more details, please download the PDF or feel free to contact us.

-

Footless land-use platform - vertical placement <aluminum alloy>

Footless land-use platform - vertical placement <aluminum alloy>Lightweight and easy to install!

【Other Specifications】 ■Corrosion Resistance Treatment: Anodizing or Electrophoretic Coating ■Color Tone: Natural Color or Customized ■Base: Concrete Ground Screw ■Reference Standard: JIS C 8955: 2017 ■Quality Assurance: 10-Year Quality Guarantee *For more details, please download the PDF or feel free to contact us.

-

A foot-operated punching stand - horizontal (aluminum alloy)

A foot-operated punching stand - horizontal (aluminum alloy)Lightweight, corrosion-resistant, easy to install!

【Other Specifications】 ■Corrosion Resistance Treatment: Aluminum alloy anodizing, carbon steel hot-dip galvanizing ■Color Tone: Natural color or customized ■Foundation: Concrete embedded / Hat-shaped steel ■Reference Standard: JIS C 8955: 2017 ■Quality Guarantee: 10-year quality guarantee *For more details, please download the PDF or feel free to contact us.

-

A vertical mounting frame for foot volleyball - aluminum alloy.

A vertical mounting frame for foot volleyball - aluminum alloy.Lightweight, corrosion-resistant, easy to install!

【Other Specifications】 ■Corrosion Resistance Treatment: Aluminum alloy anodizing, carbon steel hot-dip galvanizing ■Color Tone: Natural color or customized ■Foundation: Concrete embedded / Hat-shaped steel ■Reference Standard: JIS C 8955: 2017 ■Quality Guarantee: 10-year quality guarantee *For more details, please download the PDF or feel free to contact us.

-

Two-book foot six-use driving frame - vertical placement <aluminum alloy>

Two-book foot six-use driving frame - vertical placement <aluminum alloy>Lightweight, easy to transport and install, and excellent corrosion resistance.

【Other Specifications】 ■Corrosion Resistance Treatment: Aluminum alloy anodizing, carbon steel hot-dip galvanizing ■Color Tone: Natural color or customized ■Foundation: Concrete embedded / Hat-shaped steel ■Reference Standard: JIS C 8955: 2017 ■Quality Assurance: 10-year quality guarantee *For more details, please download the PDF or feel free to contact us.

-

Two-foot foot-operated striking frame - horizontal placement <aluminum alloy>

Two-foot foot-operated striking frame - horizontal placement <aluminum alloy>Lightweight, easy to transport and install, and excellent corrosion resistance.

【Other Specifications】 ■Corrosion Resistance Treatment: Aluminum alloy anodizing, carbon steel hot-dip galvanizing ■Color Tone: Natural color or customized ■Foundation: Concrete embedded / Hat-shaped steel ■Reference Standard: JIS C 8955: 2017 ■Quality Guarantee: 10-year quality guarantee *For more details, please download the PDF or feel free to contact us.