Piping construction: "Top Mall Method" for non-excavation installation of pipelines! Construction case study.

We will excavate underground extensively without open-cutting and install communication cables, gas pipes, and pipes for water supply and drainage.

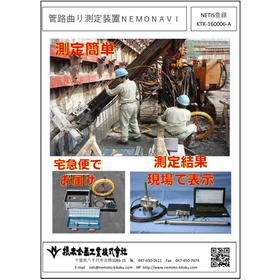

The Top Mall Method (Small Diameter Boring Method) is a non-excavation construction method for the installation of buried pipelines using a drill boring machine. It is suitable for construction in locations where excavation is difficult, such as national roads and railway tracks, and being a non-excavation method, it is a clean and simple boring method that does not produce spoil. Additionally, it is equipped with a directional correction boring method. 【Features】 ■ Boring Direction Correction Function: Curved boring is possible (Type M mainly performs straight boring) ■ Detection of the Leading Drill Head: Recognizes angles and other parameters, ensuring high safety and reliability ■ Compaction Method: No ground subsidence occurs due to being a no-spoil method ■ Short Construction Period: Approximately 30m to 50m per day per location, depending on soil type, pipe size, and working environment ■ No significant traffic disruption, allowing for daytime construction ■ Environmentally friendly clean method that does not produce industrial waste due to the lack of excavation *For more details, please download the PDF or contact us.

basic information

【Basic Performance】 1. Maximum tunnel length without excavation: 120m 2. Excavation depth (maximum): 10m 3. Maximum pipe diameter: nominal diameter 200A 4. Position detection accuracy (relative to depth): ±1% 5. Tension force: 5000kgf 【Applicable Soil Types】 1. Clay 2. Sandy soil 3. Moist soft soil *For more details, please contact us.

Price information

-

Delivery Time

Applications/Examples of results

For more details, please contact us.

catalog(2)

Download All CatalogsDistributors

Kembon Planning Industrial Co., Ltd. is a company located in Yachiyo City, Chiba Prefecture, that engages in the planning, development design, manufacturing, and construction management of industrial automation systems. If you have inquiries about automatic machines, pipe bending measurement devices, or snow melting and freeze prevention devices, please consult us. You can also view our product catalog on Ipros "Urban Development."